|

|

| Price: | $188.00/pieces 1-9 pieces |

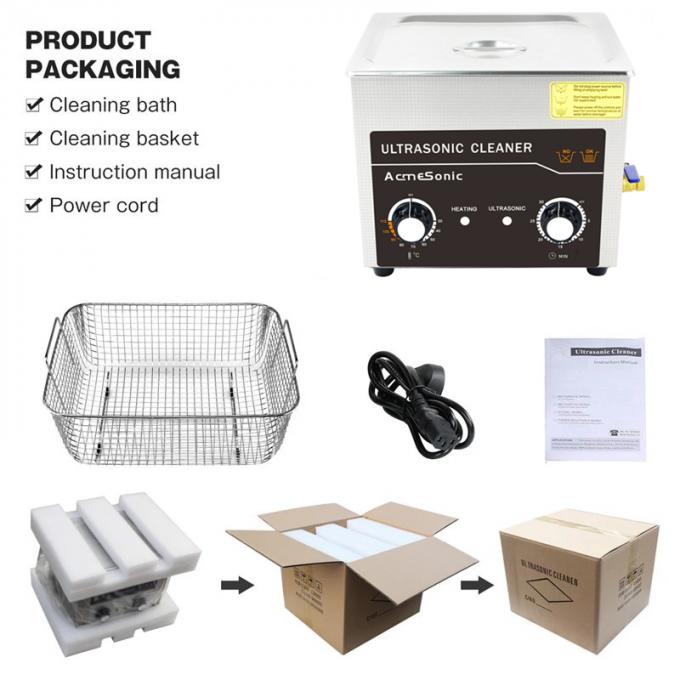

| Standard Packaging: | Customizable packaging |

| Supply Capacity: | 10000 Piece/Pieces per Week |

|

Product parameters:

|

|

|

|

|

||||

|

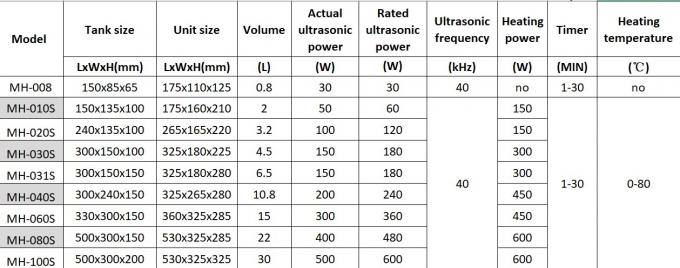

Model:

|

MH-080HJ

|

|

|

|

||||

|

Inner tank size:

|

500x300x150mm

|

|

|

|

||||

|

Product size:

|

530x330x285mm

|

|

|

|

||||

|

Packing size:

|

635x405x345mm

|

|

|

|

||||

|

Power:

|

480W

|

|

|

|

||||

|

Working Frequency:

|

40khz(customizable 28Khz)

|

|

|

|

||||

|

2Capacity:

|

22L

|

|

|

|

||||

|

Packing in carton:

|

1 pieces

|

|

|

|

||||

|

Net weight:

|

12.1Kg

|

|

|

|

||||

|

Gross weight:

|

13.7Kg

|

|

|

|

||||

|

Logo:

|

your Logo is welcome

|

|

|

|

||||

|

OEM/ODM:

|

Accepted

|

|

|

|

||||

|

Product parameters:

|

|

|

|

|

||||

|

Model:

|

MH-100HJ

|

|

|

|

||||

|

Inner tank size:

|

450x300x200mm

|

|

|

|

||||

|

Product size:

|

530x330x330mm

|

|

|

|

||||

|

Packing size:

|

635x405x395mm

|

|

|

|

||||

|

Power:

|

500-600w

|

|

|

|

||||

|

Working Frequency:

|

40khz(customizable 28Khz)

|

|

|

|

||||

|

Capacity:

|

30L

|

|

|

|

||||

|

Packing in carton:

|

1 pieces

|

|

|

|

||||

|

Net weight:

|

13.5Kg

|

|

|

|

||||

|

Gross weight:

|

15.1Kg

|

|

|

|

||||

|

Logo:

|

Meihong/Your Logo

|

|

|

|

||||

|

OEM/ODM:

|

Accepted

|

|

|

|

||||

|

|

| Price: | $188.00/pieces 1-9 pieces |

| Standard Packaging: | Customizable packaging |

| Supply Capacity: | 10000 Piece/Pieces per Week |

|

Product parameters:

|

|

|

|

|

||||

|

Model:

|

MH-080HJ

|

|

|

|

||||

|

Inner tank size:

|

500x300x150mm

|

|

|

|

||||

|

Product size:

|

530x330x285mm

|

|

|

|

||||

|

Packing size:

|

635x405x345mm

|

|

|

|

||||

|

Power:

|

480W

|

|

|

|

||||

|

Working Frequency:

|

40khz(customizable 28Khz)

|

|

|

|

||||

|

2Capacity:

|

22L

|

|

|

|

||||

|

Packing in carton:

|

1 pieces

|

|

|

|

||||

|

Net weight:

|

12.1Kg

|

|

|

|

||||

|

Gross weight:

|

13.7Kg

|

|

|

|

||||

|

Logo:

|

your Logo is welcome

|

|

|

|

||||

|

OEM/ODM:

|

Accepted

|

|

|

|

||||

|

Product parameters:

|

|

|

|

|

||||

|

Model:

|

MH-100HJ

|

|

|

|

||||

|

Inner tank size:

|

450x300x200mm

|

|

|

|

||||

|

Product size:

|

530x330x330mm

|

|

|

|

||||

|

Packing size:

|

635x405x395mm

|

|

|

|

||||

|

Power:

|

500-600w

|

|

|

|

||||

|

Working Frequency:

|

40khz(customizable 28Khz)

|

|

|

|

||||

|

Capacity:

|

30L

|

|

|

|

||||

|

Packing in carton:

|

1 pieces

|

|

|

|

||||

|

Net weight:

|

13.5Kg

|

|

|

|

||||

|

Gross weight:

|

15.1Kg

|

|

|

|

||||

|

Logo:

|

Meihong/Your Logo

|

|

|

|

||||

|

OEM/ODM:

|

Accepted

|

|

|

|

||||