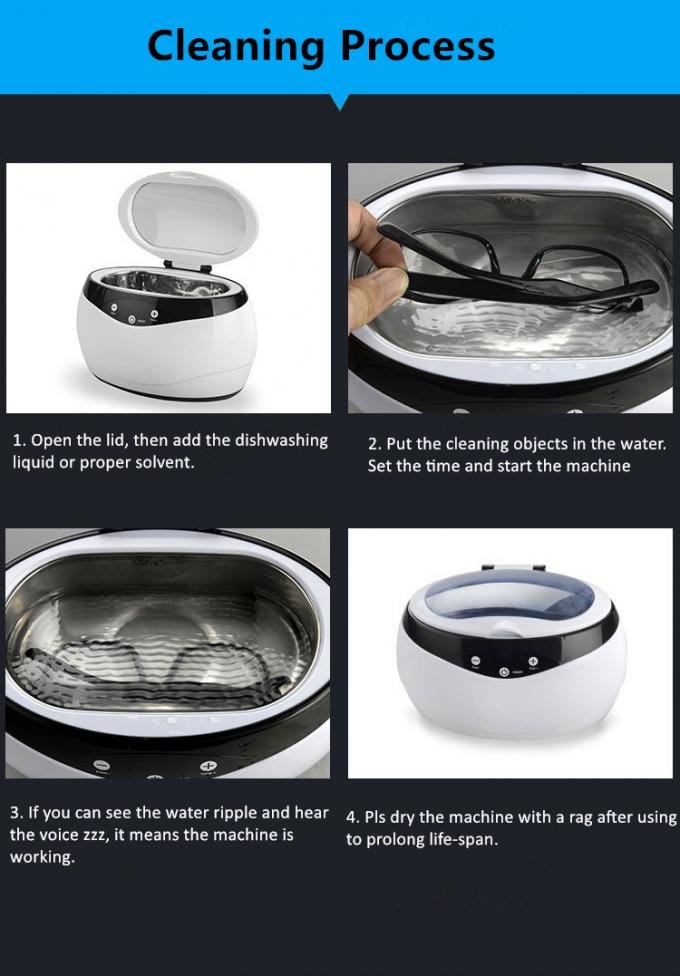

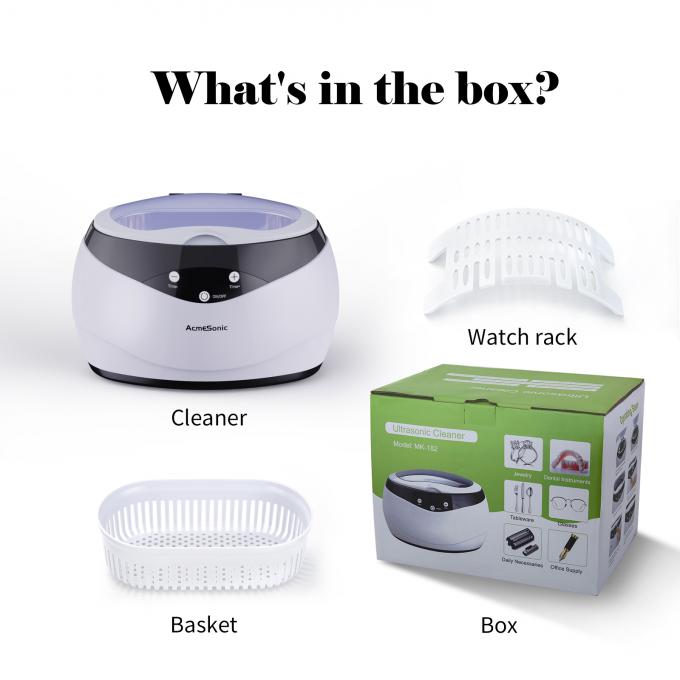

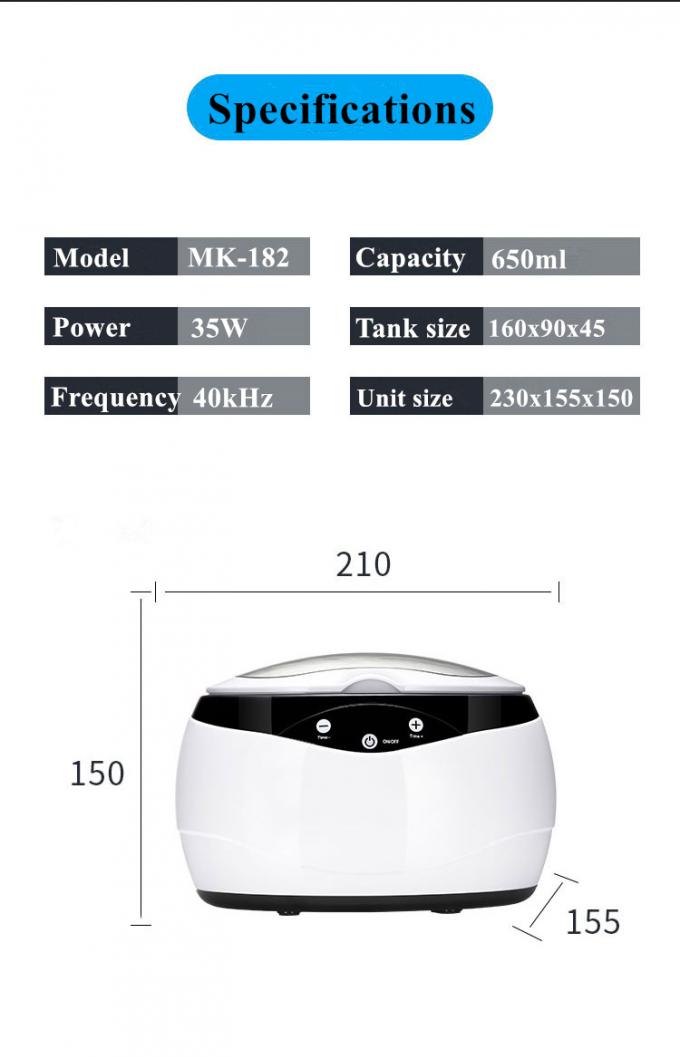

Features: High power, high frequency, larger inner tank, suitable for more cleaning.

1. Light and fashionable shape.

2. Double water-proof technology; Use it anytime you want.

3. With mechanical knob to adjust the cleaning time, adjustable timer from 0-5 minutes;

4. The inner slot space is suitable for all kinds of glasses, especially for children's corrective glasses;

5. Higher cleaning frequency for the jewelry, perfect cleaning effect beyond your imagination.

6. Patented products with intellectual property protection; Certifications: CE/FCC/ROHS/PSE/GB